Coptech WIre Industry manufactures a wide range of Enamelled Round Winding Wires. Enamelled Round Copper Wires are used in electrical machines such as motors, generators, transformers, house hold appliances, auto-electrical, refrigeration (hermetic) motors, electrical hand tools, fans, switchgears, coils & relays, ballasts and more, mainly in low voltage applications.

Bare Conductor

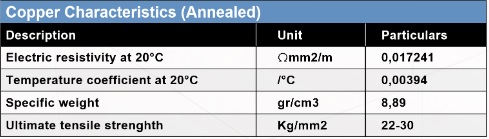

Sizes and Tolerance according to IEC 60317-0-1 standers. The standard copper wire ranges goes from 0.07 mm to 5.00 mm below are further annealed copper conductor characteristic.

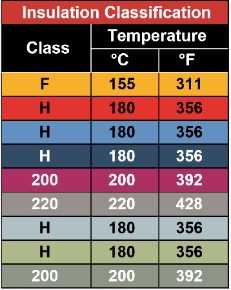

Insulation Classes

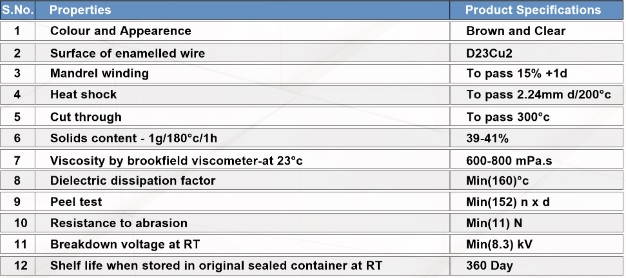

Quality Specification

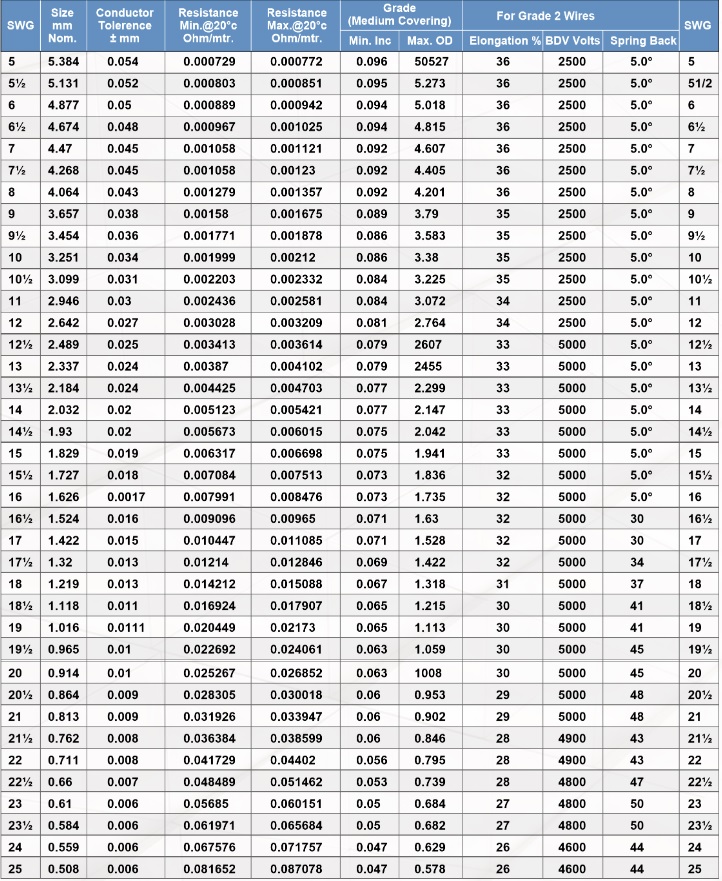

General data For Enameled Round Copper Wires

Coil Forming

Since general notes for handling wires have already been described, the below paragraphs describes some considerations for forming coils.

Considerations for Coil Forming

Dies are used for forming coils in many cases. A flaw on a die surface causes damage to the wire coating; die surfaces should be checked for damages.

Automatic Machine Winding

There is a trend toward direct coil winding to electric equipment by using an automatic coil winding machine. In general, there are a number of factors that make wires subject to harsh bending and stretching. Careful consideration must be given in advance to check coils with wires wound by a machine for damage or decreased dimensions.

Repairing at Corners

In some cases, coating wires are bent with a few mm of bend radius by using the coil of a rotating machine. It is inevitable that films are damaged at the corners to some extent; detailed maintenance is required as described earlier. It is desirable for repair materials to be identical to those of coating. In cases of inevitable situation, materials with similar mechanical, electric and thermal properties should be selected.

Handling after Coil Forming

Formed coils as mentioned above will become finished products through further stages – insulating, drying, and varnishing. These coils are assembled to stators or rotors. Extra care must be exercised to check for deformed coil shape and damaged coating during transportation or other handling processes down to the wire mounting process.

Tying of the coils should be form very soft material such as nylon thread or Cips which should not damage the surface of wire. Handel in a Plastic carets. This requires each worker to pay close attention and to be ingenious in arranging and placing coils or even to use appropriate tools as necessary. Coils shall be stored away from dust particles (particularly metal powder) and moisture. There is a recent trend toward omitting preliminary drying. However, due to the presence of strain, sweat, or moisture from enamel coatings in winding wires, preliminary drying should be performed sufficiently to improve insulation properties.

Storage

Storage of Enamel Wires in Plastic boobin as well Wounding coil form.

Please pay attention to the following points when storing wires for a long period of time :

• Never store wires in an area exposed to direct sunlight

• Avoid high-humidity environments

• Avoid special environments

• Be sure that no electric wire will hit other articles or other wires

• Never store wires in a dusty area

If magnet wires are stored properly in accordance with above, there will be no deterioration in properties even after 5 years or more have passed. However, if wires are not stored properly, for the wires for which more than three years have passed since delivery, be sure to examine the characteristics and check for problems before use.

Precautions

The insulation properties of enamelled wires are generally ensured with a very thin coating. Therefore, take special note that these wires are susceptible to external damage by sharp- edged tools.

1. Minimize stretching during the coil winding process!

Wire stretching shall be minimized during coil winding process. Stretching decreases the film thickness, leading to deterioration in properties. The smaller the stretching, the better it is. If stretching is limited to less than 5%, the property degradation of enameled wires, except for thin wires, will generally be lessened.

2. Exercise care in selecting treatment varnish

Generally, coils are varnish-treated after the coil winding process. However, various types of coil varnishes have been developed and are in use. Great care shall be exercised in combining these varnishes.

3. No releasing agent shall be dispersed

When using a chemical release agent to remove film before performing terminal soldering, special care must be exercised so that the release agent does not adhere to other portions of the coil. It is also important to neutralize the release agent and rinse it thoroughly with water after film removal. Failure to do so may cause narrow wires to become corroded and disconnected; due care must be exercised. When peeling films, be sure to wear protective gear such as goggles to prevent chemicals and separated chips from getting into the eyes.